Fancy Yarns in Ring Spinning for Industrial Applications

For more than a century, the traditional ring spinning machine has been in operation. Textile production also makes use of hole spindles, wrap spinning, open quit spinning, and hoop spinning. Different spinning techniques result in different end-product bundles of yarns, which differ in shape and physical characteristics. As much uniformity as possible should be achieved in the regular yarn shape, with the fibers intertwined to create a continuous strand of consistent thickness. Value-delivered fibers are produced in a unique way by using spinning, twisting, doubling, and wrapping. Value-delivered yarns have a significant commercial potential because of their unique visual look and the high ornamental cost they add to woven and knitted fabric and other textiles. The different price points for textiles that can be created during the spinning and post-spinning phases were introduced. Fancy yarn, a frequent production expense addition, offers ornamental discontinuities in the shape of color, texture, and visual effects, deviating from the regular structure. fancy yarns come in a variety of forms, from simple single and folded yarns to extraordinary irregular profiles or special constructions. The unique effects of decorative yarn used in clothing and home furnishings include spiral, gimp, slub, knop, loop, cowl, chenille, and snarl.

A yarn whose structure differs from that of single and folded yarns because of the purposeful addition of asymmetrical elements like loops, spirals, knots, and so forth. Fancy yarns are a subclass of yarns that are intentionally designed to introduce discontinuities, irregularities, and color variations into the yarn structure in order to enhance stylish and aesthetic impressions. They are sometimes referred to as novelty or effect yarns. Thus, high-end textiles aren’t always meant for fiber items that prioritize practicality. Many fancy textiles are manufactured by using standard staple fiber spinning devices that are equipped with specialist attachments. Others are made with a unique spinning process that uses blends of various fiber kinds or colors to create ornamental slivers. Texturized yarns made entirely of continuous filaments are regarded as fancy fabric as well. All market categories have a wide range of uses for fancy fibers in clothing. Previously, it was impossible to produce decorative fibers in large enough quantities or at a low enough cost for the mass market because to their tremendous complexity and difficulty in production and usage. On the other hand, their market penetration has expanded dramatically due to enhanced procedural control. Specifically, fancy yarns have become a more significant part of the resurgent hand knitting market even though this could be interpreted as additional proof of the market’s general viewpoint shift.

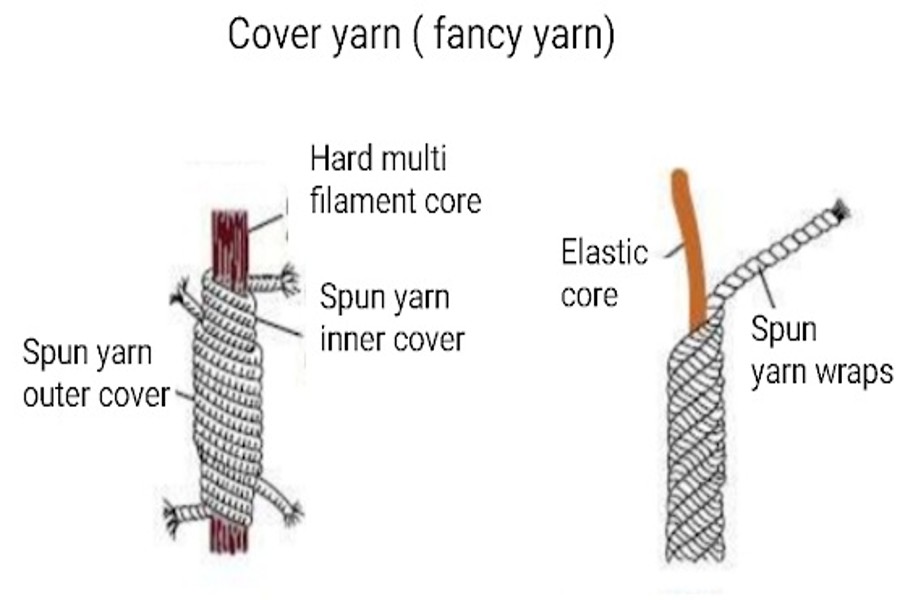

Core Spun Yarn

Both filament yarn and staple yarn are needed to make this type of yarn. The staple yarn is coiled around the filament after it has been placed in the centre. This type of yarn will combine the qualities of staple and filament yarns with a high tensile strength. To achieve conductivity, for example, copper wire is utilised as the filament. This is a form of doubled yarn as well, but the difference is that in doubled yarn, the two skeins go through specific twists, while in this instance, the filament is stabilised because just the staple yarn is wrapped around it. The best example of core spun yarn is denim. This material’s elastic foundation is made of spandex.

Marl Yarn

The simplest of the fancy effects, a marl yarn is one in which two yarns of the same count and twist, but different colors or textures, are folded together to form a balanced yarn. The yarn diagram in the below figure shows clearly both the alternation of the colors that are the primary effect of a marl yarn and the plain structure, which is that of an ordinary folded yarn. Usually these yarns are produced from spinning. after the yarn is produced, it is dyed with different needed colours and it is doubled or get twisted in the doubling machine. It has the same strength as that of doubled yarn but the texture and appearance of the yarn and the fabric made from this will be an attractive and good looking one.

Vario-siro Yarn

For producing colorful vario-siro yarn in ring spinning frame, the two rovings are fed continuously but with different speed. Feeding speeds for the two rovings are changed in such a way that the mean thickness of fiber strand entering the main drafting zone remains constant. As a result, it is possible to produce a yarn with varying color composition and constant linear density.

The main reason colorful ornamental yarn is made is to add color, which is mainly because colorful clothing has more visual impact and is therefore more valuable. However, the usage of glow fibres in garments to improve visibility at night is growing every day. When mixed with various fibres, the polyester and synthetic yarns create a variety of fancy yarns. These days, a wide range of companies sell the previously listed goods. The market value of coloured decorative yarn is expected to yield significant profits in the future. It is expected that academics will talk about new methods for producing more vibrant exotic yarns in the near future.

Featured Image:

https://www.textileadvisor.com/2021/03/different-types-of-fancy-yarns.html

Source: