Artificial Intelligence for Industrial Radiography

Industrial radiography is a non-destructive testing (NDT) method used to inspect materials and structures for defects and anomalies using ionizing radiation. It is commonly used in various industries to ensure the integrity, quality, and safety of critical components and jobs.

The primary purpose of industrial radiography is to detect internal defects, such as cracks, voids, inclusions, and discontinuities, in materials and structures. It helps ensure the structural integrity and safety of various system components.

Industrial radiography is used to examine materials, including metals, plastics, composites, and ceramics. General applications include the inspection of welds, pipelines, castings, forgings, aircraft components, and more.

Two primary types of radiation sources are in industrial radiography

- X-ray machines produce X-rays using electrical energy and are versatile for various applications.

- Radioactive isotopes include sources such as iridium-192, cobalt-60, and selenium-75, which emit gamma rays. Isotope sources are often in use situations where portability is needed.

Radiographic equipment typically includes a source of ionizing radiation, a detector (e.g., film, digital sensor, or scintillation detector), and control devices. The device can be portable or stationary, depending on the application.

There are two primary radiographic techniques used in industrial radiography

- Film Radiography: Traditional film is exposed to ionizing radiation, and the resulting image is developed, revealing defects.

- Digital Radiography: Digital sensors capture images directly, allowing for real-time inspection, immediate analysis, and electronic storage of radiographic images.

Industrial radiography is a critical tool ensuring the safety and reliability of a wider range of industrial processes and products. When conducted by trained professionals following strict safety protocols and regulatory guidelines, it helps identify defects and prevent catastrophic failures in various industries. However, it presents some hazards that have to be managed to ensure the safety of personnel, the public, and the environment.

Radiation safety

While industrial radiography is a valuable tool for quality control and safety assurance, it poses some risks to operators if not managed properly. Radiation safety is of paramount importance in industrial radiography. Radiation safety measures are crucial to protect workers, the public, and the environment from exposure to harmful radiation.

Risks associated with industrial radiography

Radiation Exposure: The primary risk to operators in industrial radiography is exposure to ionizing radiation. X-rays or gamma rays create images of the internal structure of objects, and prolonged or repeated exposure to these forms of radiation can be harmful to human health. Acute radiation exposure can lead to radiation sickness, while chronic exposure may increase the probability of cancer and other long-term health problems.

Scatter Radiation: When radiation interacts with an object to be examined, some of it scatters in various directions, including back toward the operator. Operators require proper shielding from scattered radiation by using appropriate protective barrier shield material and maintaining a safe distance from the radiation source.

Contamination: Radioactive materials used in radiography, such as radioactive isotopes or sealed sources, can pose contamination risks if they leak or are mishandled. Operators must follow strict protocols for handling and transporting radioactive sources to prevent contamination of equipment and personnel.

Equipment Malfunctions: Malfunctions or defects in radiographic equipment can lead to unintended radiation exposure. Regular maintenance, calibration, and testing of the equipment are essential to ensure its safe and reliable operation.

Operators’ Knowledge: A lack of knowledge about radiation safety, exposure limits, and emergency procedures can lead to accidents and increased risks.

Radiation Monitoring: Continuous monitoring of radiation levels in the work area and on the operators themselves is critical to ensure that exposure levels remain within acceptable limits.

Mitigate the risk is essential for companies and operators involved in industrial radiography to

- Implement strict safety procedures and protocols.

- Provide adequate training and certification for operators.

- Use appropriate personal protective equipment (PPE) and shielding.

- Regularly inspect and maintain radiographic equipment.

- Monitor radiation levels and exposure.

- Plan for automation of industrial radiography

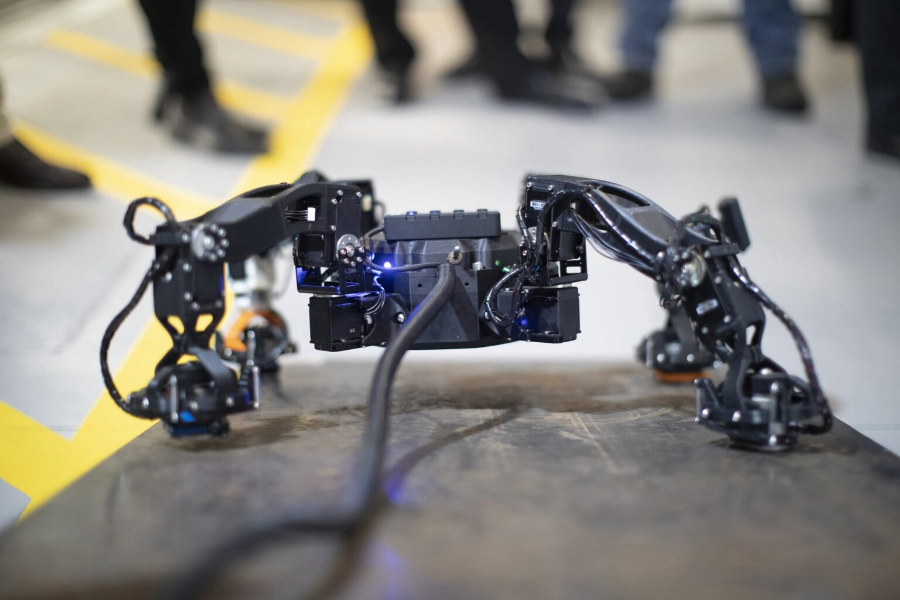

Robots in industrial X-ray

While robots are valuable for mitigating risks in hazardous operations, their deployment in industrial radiography and additional ongoing advancements in robotics and automation technologies are likely to expand their role in preventing accidents in Industrial radiography.

Remote Operation: Robots equipped with X-ray sources and detectors can be remotely operated by technicians from a safe distance, reducing the risk of radiation exposure to human operators who would otherwise need to be near the X-ray equipment during testing.

Precision and Consistency: Robots can perform X-ray inspections with high accuracy and consistency and reduce the chances of human mistakes in critical applications such as aerospace and automotive manufacturing, where the quality of welds and components is crucial.

Radiation Shielding: Robots can be designed with built-in radiation shielding to protect the operator and surrounding personnel from radiation exposure. This shielding ensures that radiation is contained within the robot’s controlled environment.

Safety Interlocks: Robotic X-ray systems are manufactured with safety interlocks and sensors that automatically shut down the X-ray source if any unexpected movements or deviations from the programmed path occur. This further minimizes the risk of accidents.

Reduced Downtime: Robots can operate continuously, 24/7 if required, without breaks or rest, and can lead to shorter inspection times, reducing the overall exposure to radiation for personnel.

Remote Monitoring: Remote monitoring capabilities allow technicians to oversee the entire X-ray inspection process without being physically present in the testing area. Real-time feedback and adjustments can be made as needed.

Conclusion

Robots used in industrial X-ray applications can be customized to accommodate specific requirements, such as the size and shape of the materials being inspected, ensuring optimal safety and accuracy.

Industrial robots can be integrated into overall safety protocols within the manufacturing or testing facility and include emergency shutdown procedures and safety training for personnel.

In summary, robots in industrial X-ray applications enhance safety by reducing radiation exposure to human operators, ensuring precision and consistency in inspections, and providing remote operation and monitoring capabilities. These advantages not only protect people in and around the equipment but also contribute to the overall quality and efficiency of industrial X-ray testing processes

Source