CLEANtube For Deposit – Free Output

CLEANtube is considered as an excellent controller of coiler drive in Reiter draw frame. Generally, while processing any fibers either natural or natural/manmade blends in draw frame, the short fibers and trash gets accumulated at the sliver duct during the coiling of sliver. So, this accumulation is removed manually once the machine stops. This cleantube generally prevents the accumulation of these trash particles and short fibers in the sliver duct which should be removed by periodic cleaning. The accumulation of short fibers is known as mouse and this is formed at the top of the silver can. The automation of the cleantube removes the formed mouse which is usually removed manually to avoid any sliver damage. With this automation of CLEANtube, manual operation is eliminated as well as the generation of soft waste is also avoided.

Benefits of CLEANtube

- As the application of this CLEANtube eliminates the manual work it saves around 300 hours of works and also approximately 0.61% of sliver waste.

- Due to this mouse accumulation, the produced sliver will result in defective places. Such defective places are avoided maximum of 200000 defects per year per draw frame.

- The spinning process attains a high efficiency level and ensures good quality of sliver.

Upgradation Of Coiler for Deposit- Free Output

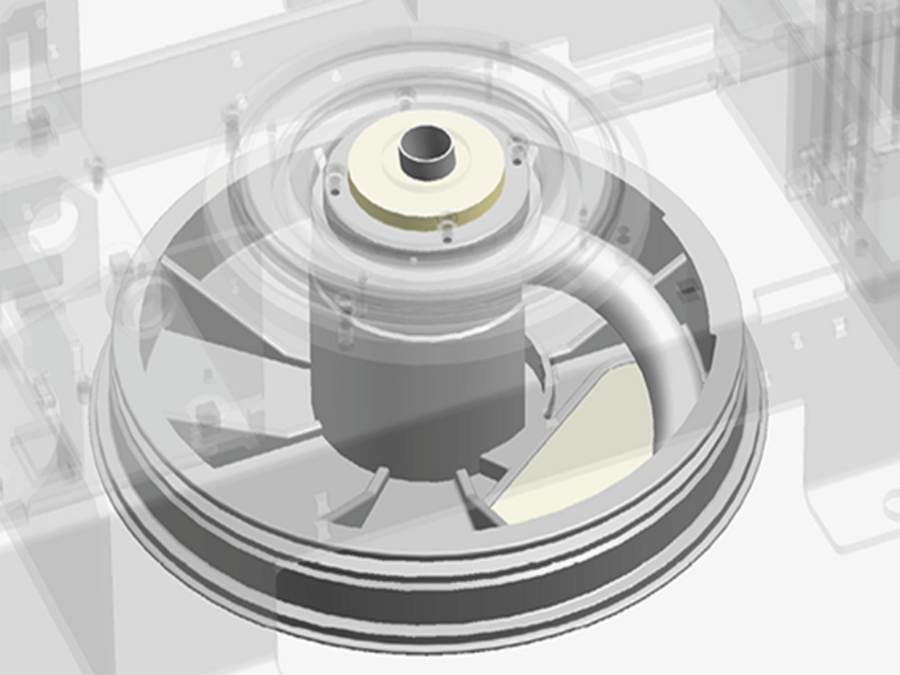

The excellent cleaning option for mouse – free protection results in precise sliver coiling and low cleaning operations. This CLEANtube conversion kit comprises a sensor named B12 EVO sensor. Its features include contactless, wear free measurement. If this CLEANtube is already installed with different sensor, it can be upgraded with the sensor B12 EVO.

The Right Draw Frame for Every Requirement

The combination of SB-D 45 draw frame without auto leveling and RSB-D 45 auto leveling provides high flexible lines with maximum efficiency. These both models are attached with a suction drive which is frequency – controlled. The vacuum at all the suction points is attached to the machine panel. The CLEANtube equipment is the unique unit which is equipped for the reliable sliver coiling and which exclusively advantageous for the processing of contaminated cotton.

The Draw Frame as Cleaning Machine

The release or emission of short fibers, dust and other fibrous particles takes place in drafting system during the drafting process of fibers. The modern draw frames brings out the cleanliness in sliver and yarn which is unparalleled to date. A device called cleaning lips has been placed over the top rollers directing the suction flow in the drafting zone. The accumulations of fibrous particles in the cleaning lips are directly removed by the suction system. The efficiency of this system is analyzed by the reflection of reduced IPI and Classimat faults in the yarn produced. This yarn quality is further enhanced by the application of CLEANtube which plays a significant role in sliver coiling without accumulations of trash and short fibers.

Consistent Yarn Quality Due to Efficient Suction

High sliver quality: The deposition of dust in the drafting system is avoided completely. Similarly sliver funnel blockage is also reduced. Due to this yarn cleanliness is improved reducing the imperfections and Classimat faults. In addition to this, the number of yarn clearer cuts are also reduced.

Easy cleaning: This cleaning works and laps in the drafting system creates unwanted stoppages in the machine. Using this equipment reduces the formation of deposits on the top rollers of the drafting system. This makes the cleaning easier and increases the productivity of the machine as well.

In-mill Study On Advantages of CLEANtube

A study has been carried out in a mill named Gupta Threads located in Punjab district. In their mill with 3744 rotor spinning machine they produce 100% cotton yarn with the count range of 7s Ne to 30s Ne. As the rotor spinning is specialized for reuse/ recycle fibers, the raw material used here is a blend of 60 to 70% waste or comber noil along with 30 to 35% of cotton.

The Observed Advantages by Equipping CLEANtube

- A work-hour of 500 can saved per draw frame per year which has been utilized for removing the mouse manually.

- While removing the mouse the operator moves around half the layer of silver. Eventhough it can be used, it leads to additional conversion costs in blowroom, carding and drawing.

- End down are reduced by eliminating the mouse.

- The mass of yarn gets increased while spinning with the mouse. This is considered as defects that are clearly visible in the fabric and has high risk for fabric rejection .

Source: