Power Integrated Modules: Revolutionizing Power Electronics

Power Integrated Modules (PIMs) represent a significant advancement in power electronics, combining multiple functions into a single, compact package. These modules integrate power switches, control circuitry, and often additional features like protection mechanisms, making them versatile solutions for a wide range of applications. In this blog, we’ll explore Power Integrated Modules, their benefits, and their applications in various industries.

Understanding Power Integrated Modules (PIMs)

Power Integrated Modules (PIMs) are semiconductor devices that integrate power semiconductor switches (such as IGBTs or MOSFETs), gate drivers, control circuitry, and sometimes protection features like overcurrent and overvoltage protection, into a single package.

Construction of Power Integrated Modules

Power Integrated Modules (PIMs) are semiconductor devices that integrate multiple power components, such as power transistors, diodes, and control circuits, into a single package. These modules are designed to handle high power levels efficiently and reliably in various applications, including motor drives, power supplies, and renewable energy systems. Here’s a breakdown of their construction:

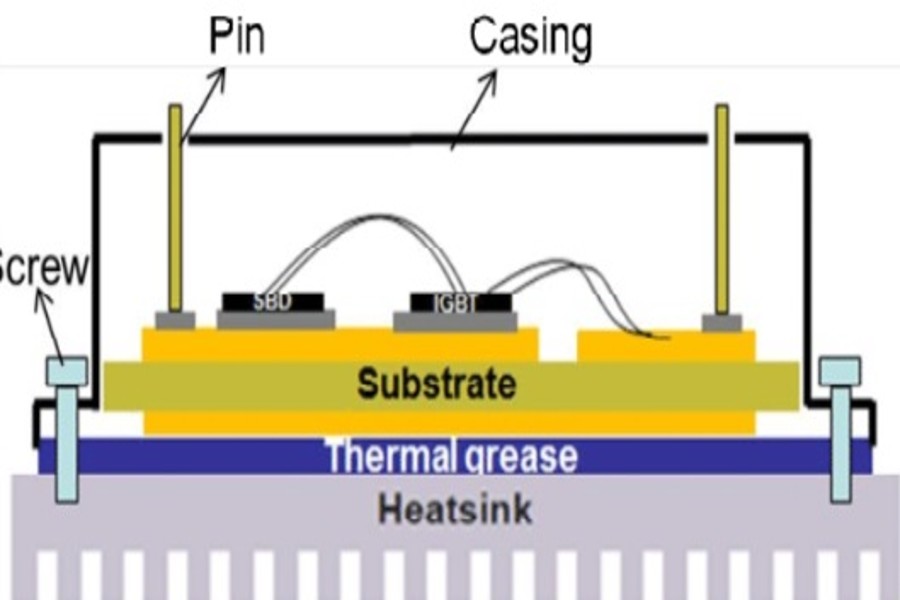

Substrate: PIMs typically start with a substrate material, which is usually a ceramic or a direct bonded copper (DBC) substrate. The choice of substrate material depends on factors like thermal conductivity, electrical insulation properties, and cost.

Power Semiconductor Devices: PIMs integrate power semiconductor devices like insulated gate bipolar transistors (IGBTs), diodes, or MOSFETs. These devices are the core components responsible for switching and controlling the flow of power within the module. They are mounted onto the substrate using techniques like soldering or wire bonding.

Control Circuitry: PIMs often incorporate control circuitry for driving and protecting the power semiconductor devices. This circuitry includes gate drivers for IGBTs or MOSFETs, protection features such as overcurrent and overvoltage protection, and sometimes even microcontrollers for advanced control functionalities.

Interconnections: Interconnecting metal layers on the substrate provide electrical connections between the various components within the module. These interconnections are carefully designed to minimize parasitic resistance, capacitance, and inductance, which can affect the performance and efficiency of the module.

Isolation and Insulation: Since PIMs handle high voltages and currents, proper isolation and insulation are crucial for safety and reliability. This is achieved through techniques like thick-film or thin-film dielectric layers, isolation barriers, and encapsulation materials.

Heat Dissipation: Efficient heat dissipation is essential to maintain the reliability and longevity of the PIMs, especially considering the high power levels they handle. Heat sinks, thermal vias, and other thermal management techniques are often integrated into the module design to dissipate heat generated during operation.

Packaging: Once all the components are integrated onto the substrate and interconnected, the module is encapsulated in a protective package. The package provides mechanical protection, electrical insulation, and environmental protection against factors like moisture, dust, and temperature variations.

Overall, the construction of Power Integrated Modules involves a combination of advanced semiconductor fabrication techniques, packaging technologies, and thermal management strategies to achieve high-performance power electronics solutions for various industrial and automotive applications.

Advantages of Power Integrated Modules

By consolidating these components, PIMs offer several advantages over traditional discrete solutions:

Space Efficiency: PIMs significantly reduce the footprint of power electronics systems by integrating multiple components into a single module. This compact design is particularly beneficial in applications where space is limited, such as automotive, industrial drives, and renewable energy systems.

Improved Reliability: By integrating critical components within a single package, PIMs minimize interconnections, reducing the risk of failures due to loose connections or thermal issues. Additionally, PIMs often incorporate advanced protection features to safeguard against overcurrent, overvoltage, and short circuits, enhancing system reliability.

Simplified Design and Assembly: Designing with PIMs simplifies the development process by eliminating the need to select and connect individual components. This reduces design complexity, accelerates time-to-market, and streamlines manufacturing processes, leading to cost savings and improved efficiency.

Applications of Power Integrated Modules

Power Integrated Modules find applications across various industries and sectors, including:

Automotive: PIMs are widely used in electric and hybrid vehicles for traction inverters, onboard chargers, and DC-DC converters. Their compact size, high efficiency, and reliability make them ideal for automotive applications where space and weight are critical considerations.

Industrial Drives and Automation: In industrial automation and motor control systems, PIMs serve as the heart of variable frequency drives (VFDs), servo drives, and other motion control equipment. Their integrated design simplifies system integration and enhances performance in demanding industrial environments.

Renewable Energy: PIMs play a vital role in renewable energy systems, including solar inverters, wind turbines, and energy storage systems. Their high efficiency and reliability contribute to maximizing energy conversion efficiency and grid stability in renewable power generation applications.

Power Integrated Modules (PIMs) represent a transformative advancement in power electronics, offering space-efficient, reliable, and cost-effective solutions for a wide range of applications. By integrating power switches, control circuitry, and protection features into a single package, PIMs simplify design, improve system reliability, and accelerate time-to-market.

Featured Image:

https://www.researchgate.net/figure/Typical-power-module-structure_fig1_308703903

Source: