Testing the mechanical strength of nanomaterials

Any substance with at least one dimension in three dimensions or one whose composition has been reduced to the nanoscale is referred to as a nanomaterial. Nanostructured materials and nanostructured components are the two general categories into which nanomaterials fall. Its structural dimensions are nanoscale in nanostructured materials. At least one of the structural elements of nanostructured elements has an outside dimension in the nanometre range. Mechanical properties of any material refer to its strength at a given load. Generally, it contains 10 parts namely hardness, toughness, fatigue strength, brittleness, plasticity, elasticity, ductility, rigidity, and yield stress. The majority of non-metallic inorganic materials are brittle, lacking attributes like toughness, ductility, elasticity, and plasticity. Additionally, certain organic materials lack stiffness and brittleness and are instead flexible.

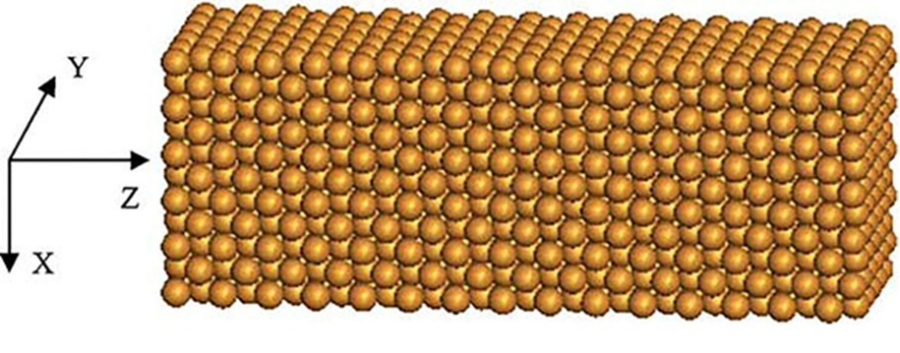

Various research is carried out in nanoparticles and it can be classified as theoretical research describes the constitutive model framework to forecast the mechanical characteristics of composites reinforced with nanoparticles and compared the model’s predictions to the outcomes of experiments. In stimulation analysis the stress-strain connection of Cu nanowires using numerical simulation and the mechanical behavior of the nanowires using the molecular dynamics technique

In experimental research, the researchers are concentrating their experimental efforts on altering nanomaterials or enhancing their mechanical characteristics. One of the examples is to enhance the mechanical qualities of the nanomaterials by incorporating nanoparticles into the matrix. For instance, adding carbon nanotubes can increase the strength of functionally graded materials.

Characterization of nanomaterials

Understanding the mechanical characteristics of nanomaterials is crucial for developing miniature thermal, optical, electrical, and electromechanical systems. However, because of scaling effects and geometric variations, nanostructures like nanowires (NWs), carbon nanotubes (CNTs), and ultrathin films tend to exhibit significantly different mechanical properties from their bulk counterparts when the surface-to-volume ratio increases along with the decreased size of structures. This means that it is difficult to infer the mechanical properties of nanomaterials from bulk properties. The aforementioned difficulties with the mechanical characterization of nanomaterials are addressed in several ways via SEM-based nanomanipulation.

To determine the Young’s modulus of individual multiwalled carbon nanotubes (MCNTs), an in situ bending test is used. A piezoresistive atomic force microscope (AFM) probe was used to measure the bending force. The in situ buckling test can be used to estimate the Young’s modulus of each MCNT. By using nanomanipulation to EBID-fix an individual MCNT using an AFM cantilever probe, the buckling force was determined by measuring the cantilever beam’s deflection. The mechanical characteristics of the sample, such as Young’s modulus, failure strain, and fracture strength, can be measured via microelectromechanical system MEMS-based tensile testing, which has been used to characterize 1D nanostructures (such as nanowires, nanotubes, and nanoribbons). Using FIB etching and deposition, typical AFM cantilevers were changed to create several functional instruments for cell mechanical characterization in Environmental SEM (ESEM). Bend testing using MEMS technology can also be used to assess the mechanical properties of nanomaterials. A cantilever beam is manipulated by a comb-drive electrostatic actuator and bent against a fixed block in a standard MEMS-based bend testing setup. suggested a MEMS-based system that bends tests an aluminum cantilever beam with a thickness of 100 nm using a comb-drive electrostatic actuator. The actuator’s pre-calibrated loading equation was used to determine the applied force and high-resolution imaging was used to detect the beam deformation. There are two types of actuators for in-plane and out-of-plane bend testing of thin-film (700 nm) polysilicon microstructures: a parallel-plate electrostatic actuator and a rotational comb-drive actuator. The bottom of micrometer-think polysilicon MEMS structures can be joined to nanometre-thick polysilicon structures by the use of a commercial surface micromachining method, which was used to fabricate the microstructures. The necessity for nano sample addition following MEMS device creation is eliminated by this fabrication technique.

Nanoparticle research spans three key categories: theoretical, simulation, and experimental studies. Theoretical investigations involve modeling and predicting nanoparticle behavior, guiding subsequent research. Simulation studies employ advanced computational techniques to simulate nanomaterial interactions and properties. Experimental research is conducted through various characterization processes, such as in situ bending tests, providing real-world insights into nanomaterial behavior. Environmental scanning electron microscopy (SEM) enables observation under specific conditions, enhancing understanding of nanoparticle environments. Micro-electromechanical systems (MEMS) facilitate precise manipulation and measurement of nanomaterials. These diverse approaches collectively contribute to advancing our understanding and application of nanoparticles across scientific and technological domains.

Source